Fully automatic ball valve assembly machine 059

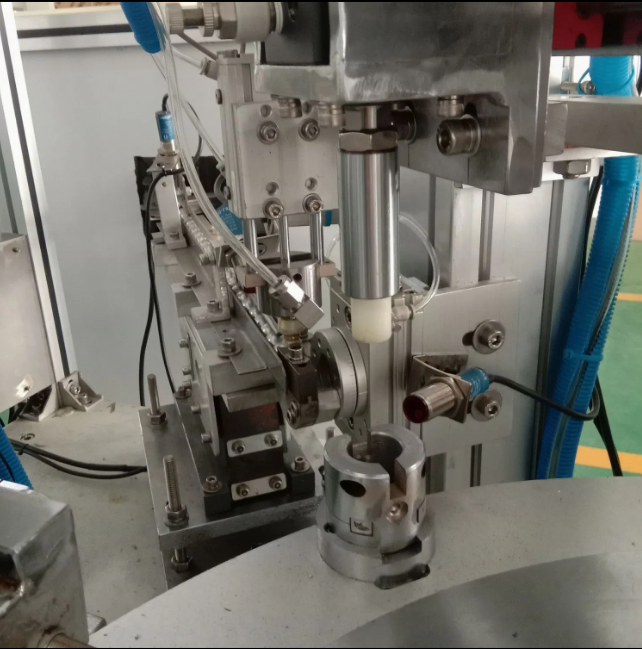

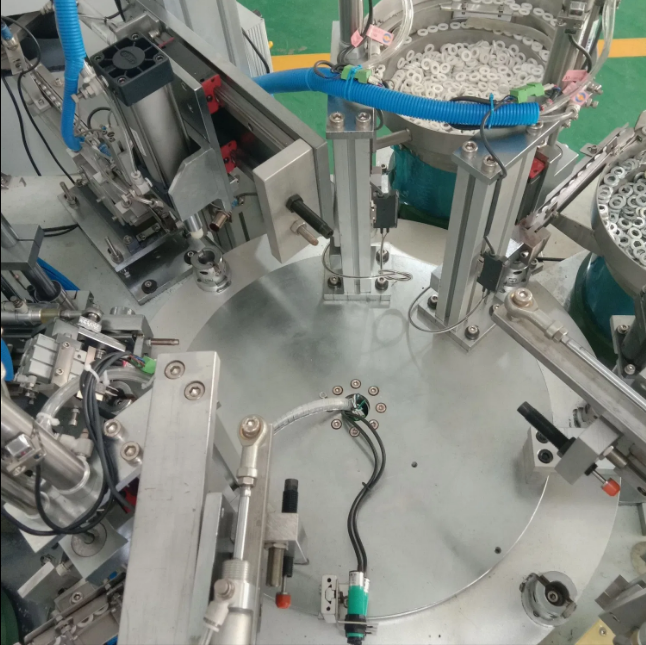

Ball valve assembly automation that can manually load the valve body and bonnet, and can also automate the assembly process sequentially with an 8-station turntable, vibratory feeder, and multiple sets of robotic arms. It completes the following steps synchronously: installing the plastic gasket on the valve body and bonnet, gluing the bonnet, flipping the bonnet, tightening the bonnet, and finally removing the finished product. This allows all components to be assembled into the final product in a single step, reducing labor costs and increasing production efficiency.

PRODUCT PROFILE | |

Product item |

|

Model NO. | CAM059 |

Main motor power | Customized optional (kw) |

Servo motor power | 0.6KW |

Size | 155*170*180CM |

Weight | 800KG |

Assembly speed | 4 seconds/piece |

Torque setting range | 10-100N.M |

Reducer speed ratio | 7:1 ; 8:1 |

pressurized air | 4MPa |

power supply | 220V |

Delivery | 12-15 days |

Shipment | By sea, By air, By express |

Features:

1. Each step is strictly in accordance with the production steps to ensure good product quality

2. Choose excellent materials to ensure quality

3. Introduction to the operation to ensure the efficient production efficiency of the machine

4. Tight packaging to ensure the safety of the equipment during transportation to the greatest extent

5. Product after-sales guarantee

INQUIRY

CATEGORIES

CONTACT US

Contact: Mr.Wu

Phone: 13736965797

E-mail: info@wenzhoucam.com

Whatsapp:➕86 13736965797

Add: Qiaoxia Town, Yongjia County, Wenzhou City, Zhejiang Province China